The History of the Worshipful Company of Gunmakers

A brief overview of the history of the Gunmakers Livery and the London Proof House.

The Early Years to 1675

As with all Livery Companies, the Gunmakers’ origins lie amongst the crowded lanes of the City but more particularly in the shadow of the Tower of London, where trades had sprung up to service the Tower and its military requirements.

For over a hundred years before the formation of the Gunmakers Company, firearms had been manufactured by artisans who were members of other established Companies such as the Armourers, Cutlers and Blacksmiths – a natural extension of their existing trades. Competition was stiff; it was a new technology and not only were the existing Companies keen to pursue it, there was also competition from the influx of gunmakers from France and the Low Countries who based themselves around the Tower and in the Minories.

Gunmakers had been petitioning Elizabeth I for the recognition of their craft by the grant of their own Company since 1581. The threat of the Spanish Armada in 1588, and the need for standardisation of firearms to support the forces raised to defeat it, suggested that it might be granted. However, resistance from the existing Companies ensured that, although a Commission was created to oversee quality and proof, the majority of its members were from the Blacksmiths and Armourers who insisted on exercising their existing rights.

Eventually, after petitioning the King in 1636 for the grant of a separate Gunmakers’ Company by Royal Charter, the Attorney General was appointed to hear the opposing views and to come to a decision. The result was the granting of the Gunmakers’ Charter by Charles I in 1637, reflecting the energy of our first Master, Henry Rowland. This was not universally well received and again opposition was encountered from the older Companies. It was not until the Protectorate of Oliver Cromwell that a petition was submitted to the Court of Aldermen. The Charter was enrolled at Guildhall in 1656, and by 1663 all gun making apprentices were bound to the Company. Subsequently Charles II approved the Ordinances of 1671 giving more detail to our ways of working.

The Charter granted Members of the Company the rights to not only make and trade in firearms, but also to proof, test with an overcharge, and mark firearms in London and a 10-mile radius, as well as to search and seize any deemed unlawful. No guns were to be sold unproved and, if they were, then they would be declared forfeit:

- “The stamp of GP crowned on all such hand guns, daggs, pistols and parts of guns as upon search, view, gage, trial and proof shall be found sufficient serviceable and of good material. Rejection and forbear to mark all others”

- The proof overcharge “With good and sufficient gunpowder, the weight of a bullet of lead sizeable to every several gun according to the bore of the piece together with the said sizeable bullet and rammed with paper before and after the bullet”

The first proof house was near to the Tower next to the City Wall on ground owned by John Silke but by 1662 this was declared ‘in danger of falling down’. The Company moved elsewhere until 1675 when it was agreed that it should move to land in the ‘open fields’ of the parish of St Mary Whitechapel on part of the site The Proof House occupies today.

1637 to 1813

During this period the gun matured as a weapon, a standing Army was put in place from the 1680s and the muzzle-loading flintlock triumphed. The military gun making district around the Tower expanded eastwards to serve the Board of Ordnance, the East India Company and others. To the west, a second gun making district grew up around the Royal Court at the Palace of St. James. A long century of conflict until the end of the Napoleonic Wars in 1815 created a carefully managed military demand from the State. The Members of the Gunmakers Company allied to secure an appropriate share of this. This dynamic ultimately led to the emergence of the ‘London Gun,’ with the Gunmakers Company exerting its control across the century through the power of proof.

The first proof house on this site was likely built in 1676 by the landowner Michael Pratt, a carpenter, but given the Company’s early tendency to blow up the building, there was a frequent need to rebuild it. The Company secured the freehold of the land in 1713 and an enlarged proof house was constructed. This building had to be extensively repaired in 1757-8 as it was in a ‘ruinous’ state and most of the current proof house dates to 1826. The Company continues to maintain and preserve this unique listed building, while carrying out its work of proof.

From 1709, proving arms for the East India Company was an important source of income. It required significant effort to retain this business, particularly in the 1770s when private proof was available from The Tower. A Store House was built next door in 1807, and the East India Company remained clients until its dissolution in the 1850s.

Of the many families that have been involved in the Company the Barnetts were the most prolific. Starting with Robert Barnett in 1761, family members served as Master 30 times, ending with Harold Barnett in 1943. They were the biggest manufacturers of guns for export and therefore had a strong interest in influencing the trade. Their manufacturing was based close to The Proof House; first in the Minories, then Duncan Street and Leman Street, a short walk from here.

In the 18th Century The Lord Mayor and Aldermen of the City of London approved the Company as a Livery. This meant that Liverymen could enter by Redemption as well as Servitude and so play a full part in the governance of the City. However, the winds of change were beginning to blow...

During the 1780s Henry Nock, Master in 1802, began to work with the reforming Master General of the Ordnance, the Duke of Richmond, on a new musket. Nock had a fine shop near St Paul’s and a manufactory in Whitechapel. By the end of 1795 he had a steam engine and had made over 12,000 interchangeable musket locks. This pioneering gunmaker had brought the industrial revolution to Whitechapel.

Technical and economic changes continued. By 1800 Ezekiel Baker was making ‘his’ rifle in Whitechapel; after experiments in the Tower the Reverend Alexander Forsyth patented percussion ignition in 1807; and in 1808 the State started to seriously invest in military gun making capacity.

1813 to Today

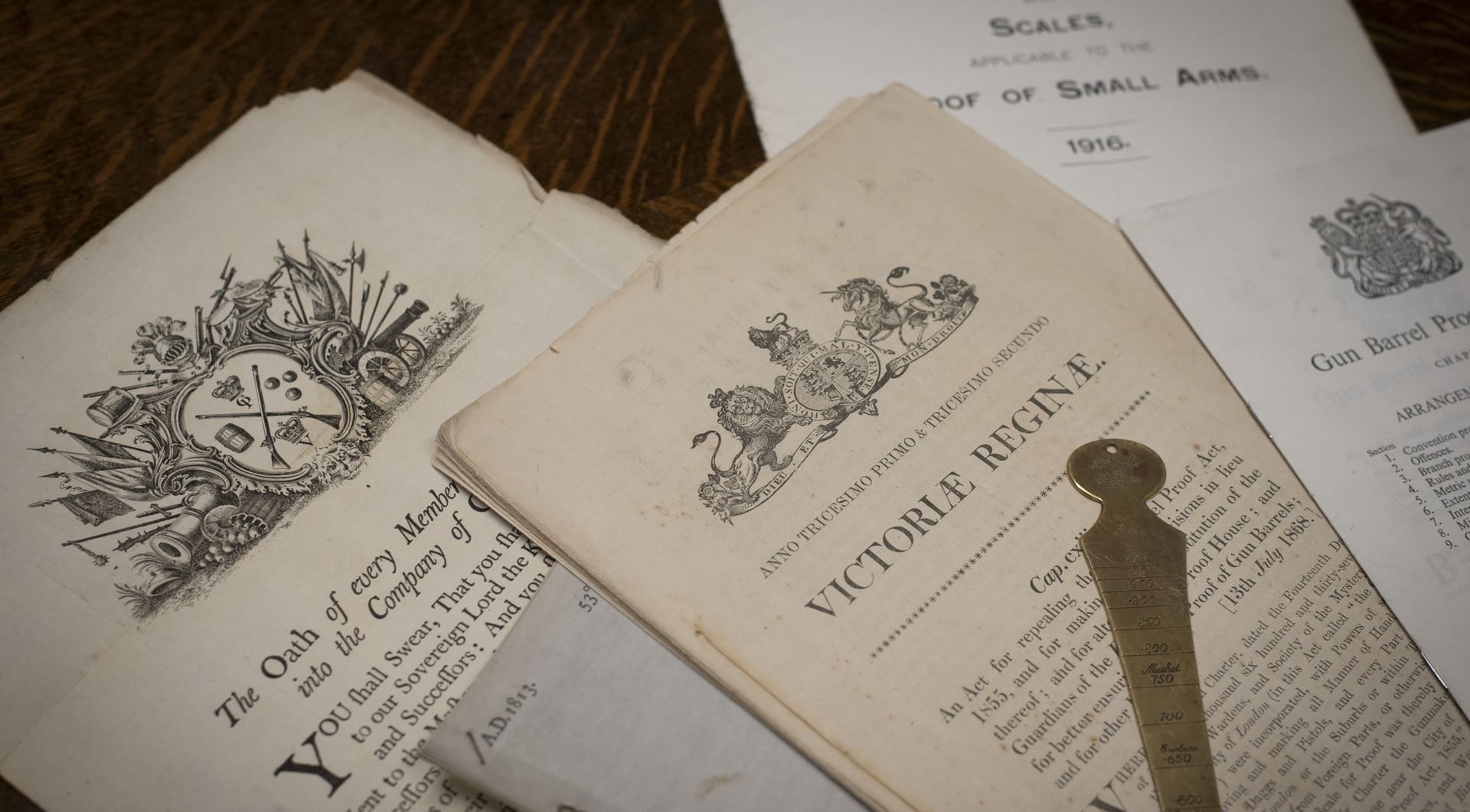

With the passing of the first Proof Act in 1813, the Company’s activities were enshrined in law as well as establishing another proof house in Birmingham. We remain one of only two London Livery Companies to have a statutory role in British legislation. The following two centuries saw changes in firearms and ammunition and the act of proof and its associated rules have become correspondingly more precise to ensure the safety of firearms and their users.

The primary legislation that governs all proof activities carried out here today is the Gun Barrel Proof Act of 1868. This reinforced and increased the Company’s powers and set down penalties for counterfeiting proof marks. The 1868 Act has been amended twice: in 1950, to allow for proof prices to be increased; and in 1978, to align British proof law with the international convention for proof standards – (CIP) Commission Internationale Permanente Pour L’Epreuve Des Armes A Feu Portatives.

Supplementary Rules of Proof allow our methods and safety standards to adapt more quickly to technological changes. They also represent a growing understanding of safety margins, and greater regularisation within our industry.

The first of these was introduced in 1875 to allow for barrels with ‘choke’ constriction in the muzzles. This was followed by a standardisation of bore diameters for proof in 1887 and the introduction of the first marks for smokeless ‘Nitro’ powders in 1896. The current ‘Nitro’ proof mark – an arm bearing a scimitar, taken from our coat of arms – was introduced in 1904. Chamber depth was added to marks in 1925 and the proof pressure included since 1954. This also saw the optional replacement of imperial measurements with metric, which was formalised in 1989. The most recent changes, introduced in 2006, covered proof levels for both higher pressure Lead and Steel Shot loads.

In 1863, the East India Company’s former store house was repurposed as the Livery’s Committee Room, then expanded to the Hall in 1871. It was sold in 1927 and repurchased by the Company in 2007. In 1875, a new Explosives Act required special rules for the safe storage of Black Powder in The Proof House. A purpose-built copper-lined magazine which held up to 560lbs of powder (¼ of a ton) was situated in the roof space over the front door to minimise the damage that might be caused in the event of an explosion. It remained in use until around 1927.

Alongside these changes to the act of Proof, the wider gun trade had evolved. With the demise of the East India Company in the 1850s and the increased use of machines at the enlarged Royal Small Arms Factory at Enfield Lock, civilian sporting arms became the Company’s primary business. It was not until 1983 that the Company became responsible for military proof once more with the privatisation of military small arms manufacture, opening a branch proof house at Enfield Lock and then Royal Ordnance Factory (ROF) Nottingham.

The increased importance of sporting arms was reflected in the Masters of the Company with James Purdey the Elder becoming the first of 19 Purdey Masters in 1841. In 1892, a Supplementary Charter changed the date of the election of a new Master and in 2003 The Gunmakers' Company Charitable Trust was formed with the principle aim of supporting the craft skills associated with traditional gun making.

We continue to proof firearms under statute for the public good.